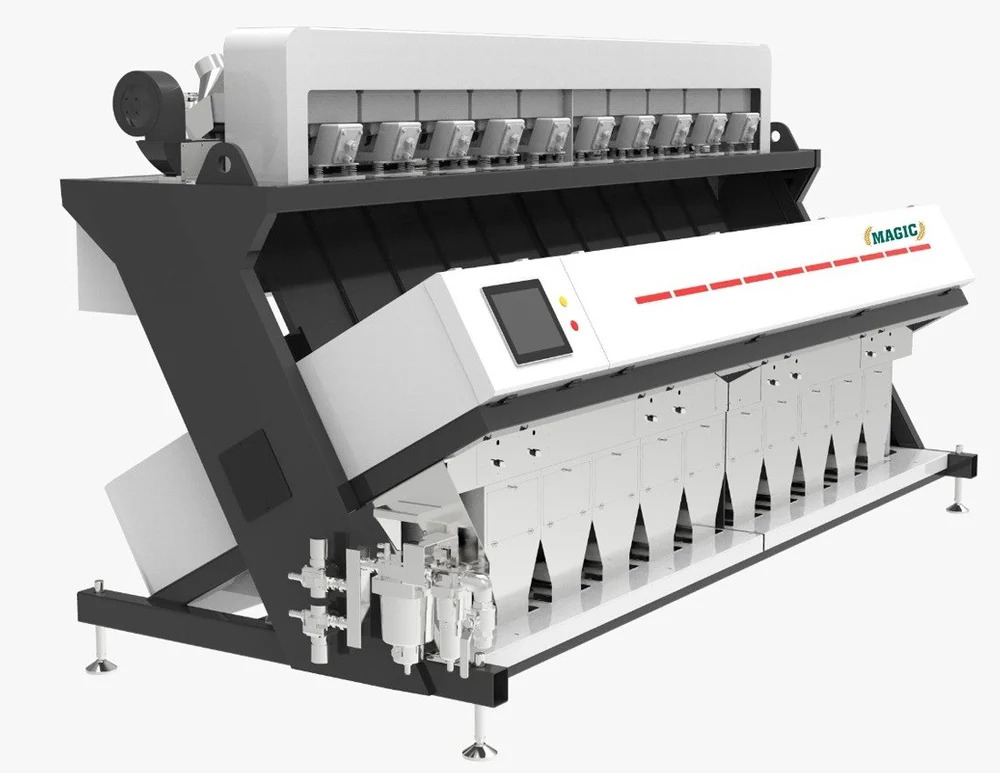

3000Kg Plastic Flakes Color Sorter

Price 1400000 INR/ Unit

MOQ : 1 Unit

3000Kg Plastic Flakes Color Sorter Specification

- Air Pressure

- 10 Bar

- Weight

- 500 Kilograms (kg)

- Capacity

- 3000 Kg/hr

- Usage

- Industrial

- Accuracy

- 99 %

3000Kg Plastic Flakes Color Sorter Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About 3000Kg Plastic Flakes Color Sorter

Introducing the 3000Kg Plastic Flakes Color Sorter-a radiant blend of precision and performance for industrial needs. This top-tier machine boasts a prodigious capacity of 3000 Kg/hr, powered by 99% accuracy and robust operation at 10 bar air pressure. Crafted for invincible efficiency and reliability, it's your solution to seamless color sorting under any procurement demand. Unlock unbeatable price advantages as a service provider, supplier, or trader in India. Markdown your sorting processes with a weight of just 500 kg-the ideal choice for elevating production quality.

Diverse Applications & Competitive Edge

The 3000Kg Plastic Flakes Color Sorter extends its prowess beyond standard plastic reprocessing. Its advanced detection technology is equally effective on various industrial recyclables, ensuring each batch achieves the highest purity. Suitable for smooth, granular, or textured application surfaces, this machine guarantees minimal waste and rapid throughput. Unmatched competitive advantages include high reliability, operational efficiency, and reduced maintenance, giving users a distinct edge in demanding industrial environments.

Packaging, Samples & Export Policies

Each 3000Kg Plastic Flakes Color Sorter is meticulously packaged for maximum protection and delivered with express shipping options for both domestic and export markets. In line with international standards, detailed packaging ensures safety during transit. Interested buyers can procure samples, which are available upon request; standard charges may apply according to the company's sample policy. This approach guarantees product integrity before large-scale procurement and reinforces our commitment to quality and customer satisfaction.

Diverse Applications & Competitive Edge

The 3000Kg Plastic Flakes Color Sorter extends its prowess beyond standard plastic reprocessing. Its advanced detection technology is equally effective on various industrial recyclables, ensuring each batch achieves the highest purity. Suitable for smooth, granular, or textured application surfaces, this machine guarantees minimal waste and rapid throughput. Unmatched competitive advantages include high reliability, operational efficiency, and reduced maintenance, giving users a distinct edge in demanding industrial environments.

Packaging, Samples & Export Policies

Each 3000Kg Plastic Flakes Color Sorter is meticulously packaged for maximum protection and delivered with express shipping options for both domestic and export markets. In line with international standards, detailed packaging ensures safety during transit. Interested buyers can procure samples, which are available upon request; standard charges may apply according to the company's sample policy. This approach guarantees product integrity before large-scale procurement and reinforces our commitment to quality and customer satisfaction.

FAQ's of 3000Kg Plastic Flakes Color Sorter:

Q: How does the 3000Kg Plastic Flakes Color Sorter achieve such a high accuracy rate?

A: The sorter uses state-of-the-art detection sensors and advanced color recognition algorithms to segregate plastic flakes with 99% accuracy, ensuring nearly flawless separation outcomes in industrial processing.Q: What industries can benefit most from this color sorter?

A: Industries involved in plastic recycling, manufacturing, and raw material processing will greatly benefit from this machine, particularly those requiring stringent color separation and purity standards.Q: When is the recommended time to procure replacement parts or schedule maintenance?

A: It is advisable to schedule regular maintenance based on operating hours, usually every six months, or as specified in the usage manual, for optimal long-term performance and minimal downtime.Q: Where can I arrange to view a sample or receive a demonstration of the sorter?

A: Samples and demonstrations can be arranged directly through authorized service providers or suppliers in India. Contact your nearest dealer to request further details or to organize a viewing.Q: What is the process for express shipping and international export of the sorter?

A: Upon confirmed order, the product is securely packaged and shipped via express logistics partners, with full compliance to export standards. Shipping charges and timelines are shared with customers based on destination and urgency.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sorting Machine Category

Salt Optical Sorting Machine

Price 3000000 INR / Unit

Minimum Order Quantity : 1 Unit

Accuracy : 99 to 99.9% %

Weight : 2430 Kilograms (kg)

Capacity : 8 T/hr

Power : 17.5 Horsepower (HP)

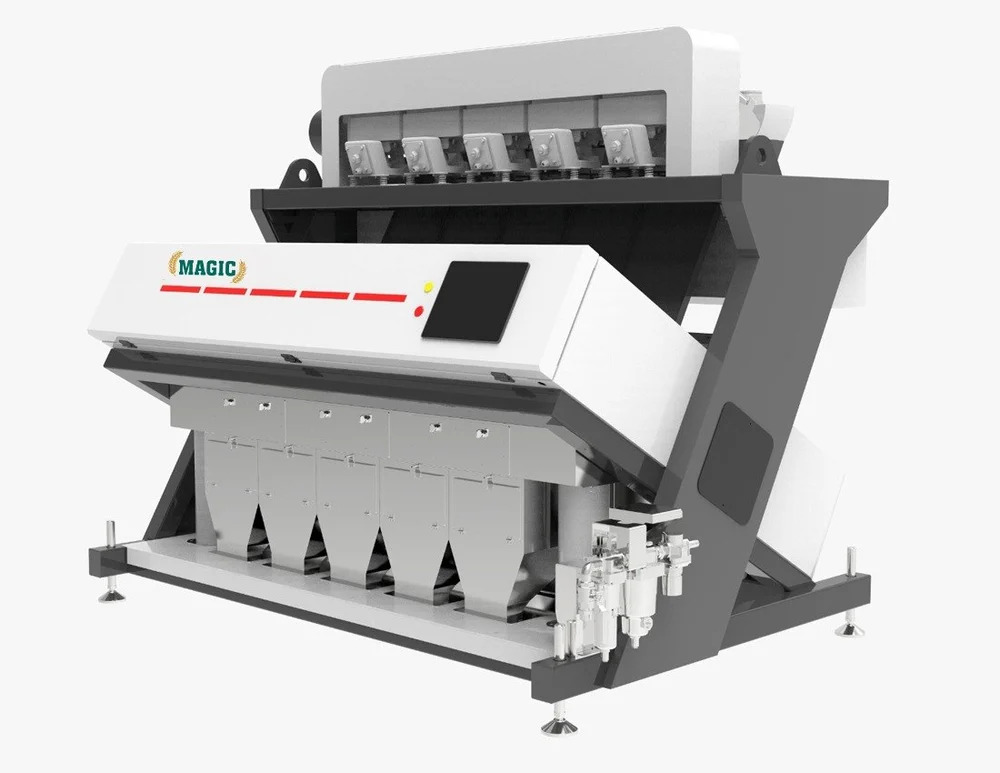

5 Ton Coffee Bean Sorting Machine

Price 1800000 INR / Unit

Minimum Order Quantity : 1 Unit

Accuracy : 99 %

Weight : 500 Kilograms (kg)

Capacity : 5 T/hr

Power : 4.5 Watt (w)

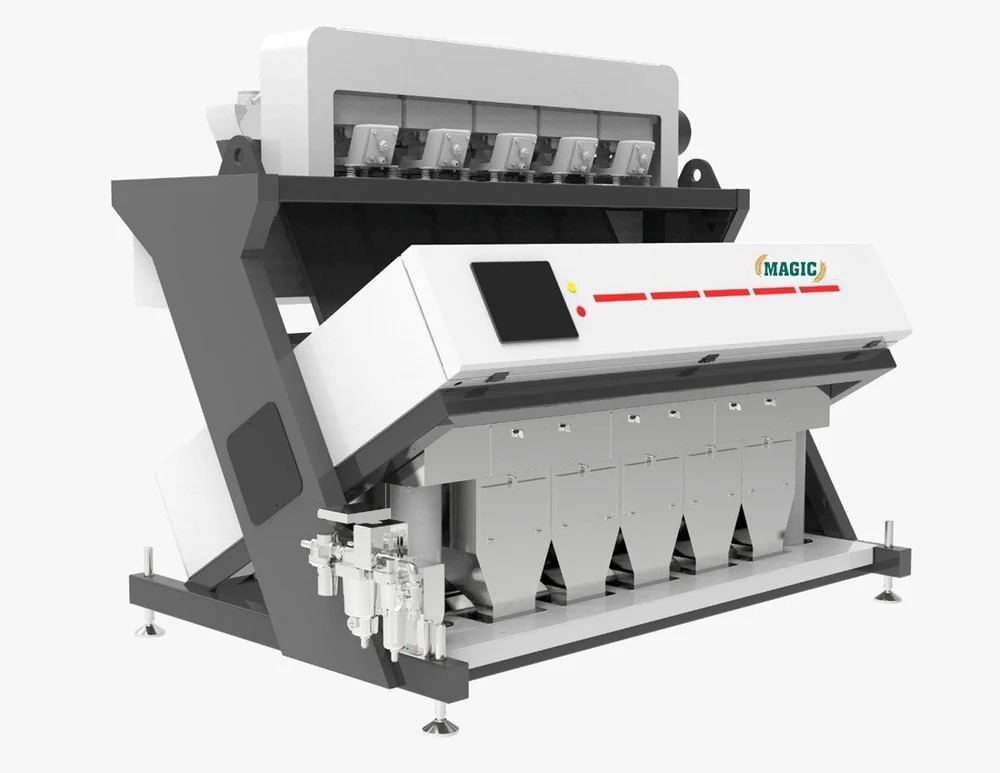

3 Ton Grain Sorting Machine

Price 600000 INR / Unit

Minimum Order Quantity : 1 Unit

Accuracy : 99 %

Weight : 500 Kilograms (kg)

Capacity : 2 T/hr

Power : 4.5 Watt (w)

1 Ton Wheat Color Sorter Machine

Price 800000 INR / Unit

Minimum Order Quantity : 1 Unit

Accuracy : 99 %

Weight : 500 Kilograms (kg)

Capacity : 1 T/hr

Power : 3.5 Watt (w)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry